3D printing is still a craft, to a large extent. For all but the simplest functional parts, a successful print requires at least a little thought about filament type, layer height, number of shells and top/bottom layers, infill density and type, and so on.

One subtle parameter is part orientation. In some processes, such as on a 6-axis CNC mill, this might not matter. With FDM 3D printers (ones that use plastic filament), it does. Printed parts are far stronger in the X/Y plane, where layers are laid down, than they are in the Z axis. A long, thin part such as a conductor’s baton would be fairly strong if printed horizontally on the bed. The same design, printed at the same settings, would be very weak if printed vertically (if you could get it to stay on the bed at all.)

In addition, you can often minimize or eliminate the need for support material simply by changing the part orientation so that no overhangs exceed 45 degrees or so. This saves material, but more importantly, makes part cleanup a lot easier.

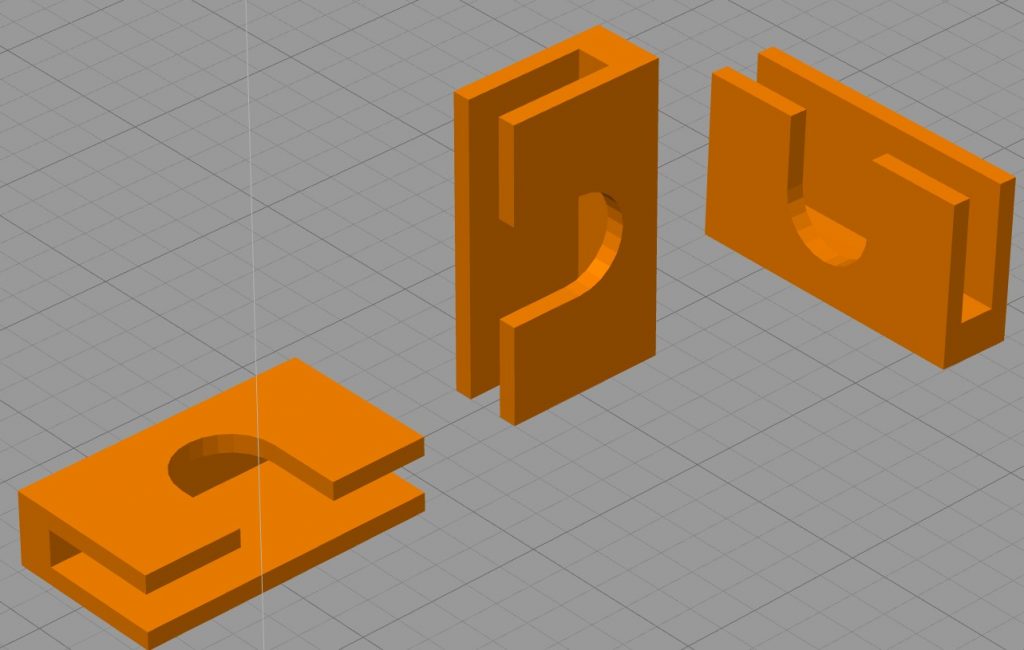

As an example, consider the following cable clip. Which of the three orientations would be best?

ignoring symmetries and clearly-worse options.

The contestant on the right seems to be the best choice, at first. It can print in place with zero support needed. This also means it will pop right off the bed ready to use. Is it viable? Let’s take a closer look.

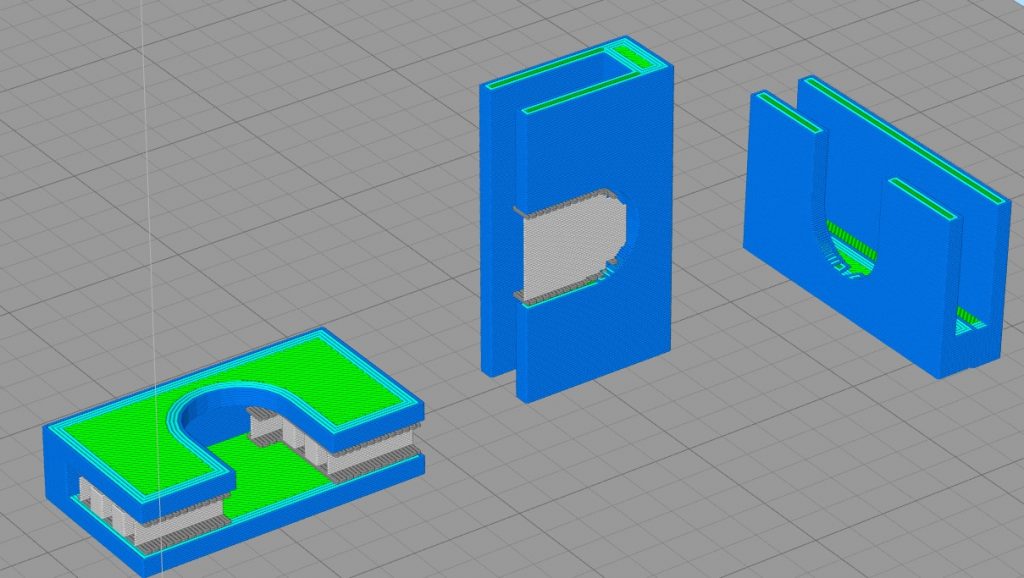

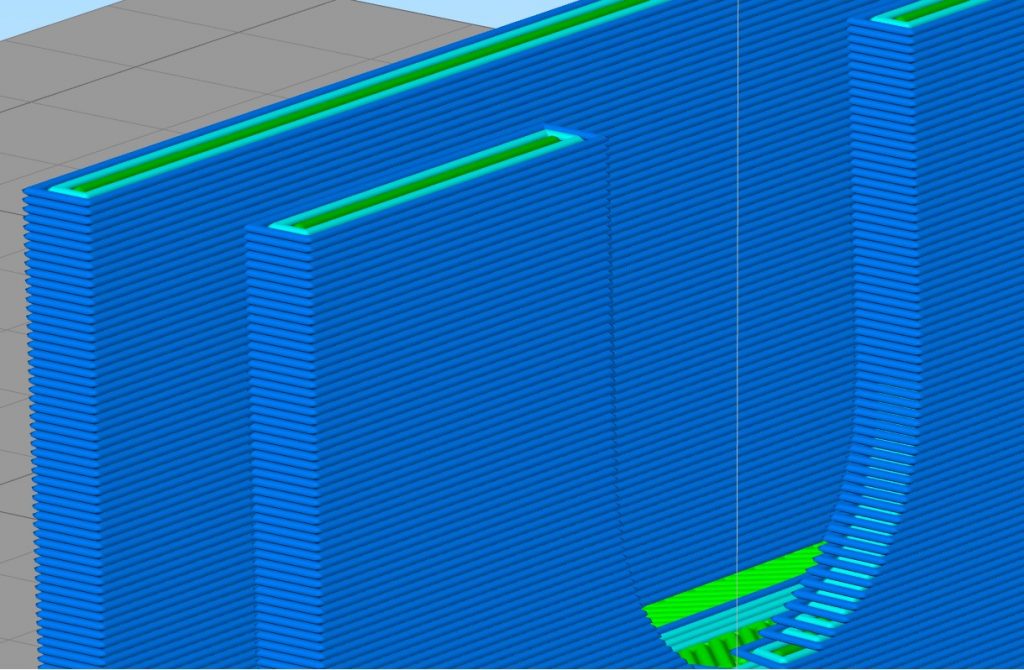

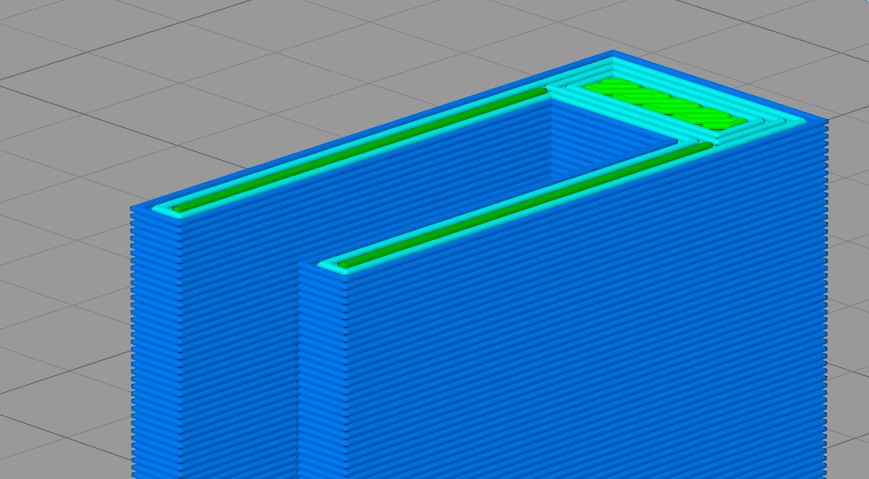

First, we use Simplify3D to slice the three models, adding support where it is needed. Let’s look at the model on the right…

This orientation isn’t terrible, but it isn’t perfect. It won’t require any support, but those clip arms are rather weak, and could break under the stress of being clipped onto the bed.

But at least it isn’t the one on the left…

This one’s a disaster. That support is needed to print those cantilevered overhangs — and it will be a pain to remove unless it’s printed in something exotic like water-soluble PVA.

To add injury to insult, it’s the weakest of the three, too. The tension from clipping onto the bed will stress the back of the clip by the lever principle. Even money says it breaks while you’re trying to get the support removed. Double Plus Ungood. Let’s look at the third option.

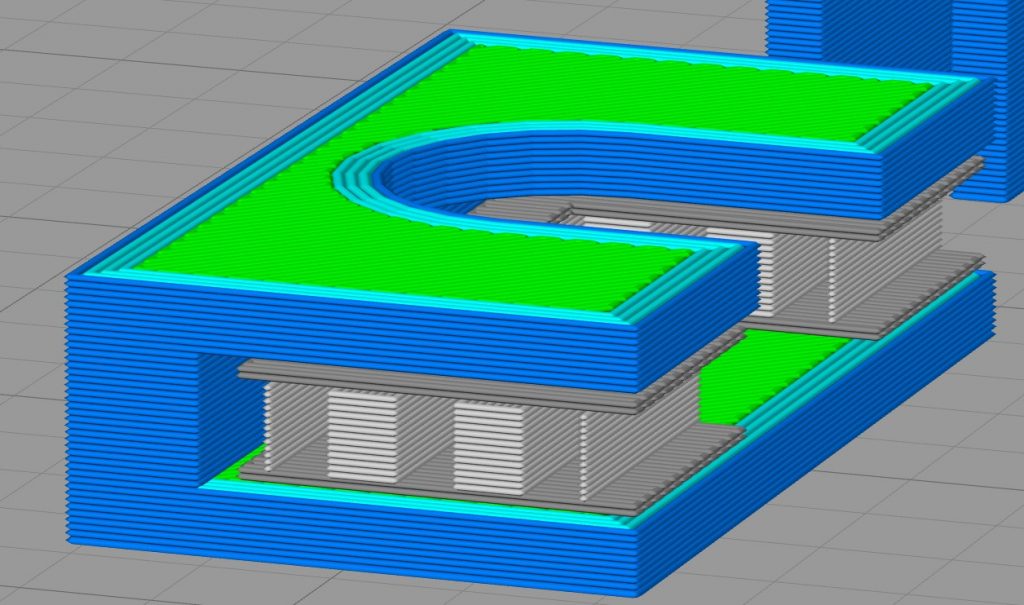

This one’s the winner. While it does need some support in the cable cutout — and while it’s weak along its length — it is strong in the one dimension that matters — the one that has to hold itself to the bed.

Now to figure out how to insulate it from the heat, so I don’t have to print it out of Nylon…